REBUILT ENGINES

Quality Rebuilt Engines | Discover our comprehensive rebuild plan for engines.

Certified rebuilders ensure top quality and reliability.

Warranty included.

Reliable Rebuilt Mining Engines

Engine Block

Cylinder Head

Crankshaft

Camshaft

Pistons and Con Rods

Bearings

Gaskets and Seals

Valvetrain Components

Timing Components

Fuel System Components

Lubrication System

Cooling System

Intake and Exhaust System

Ancillary Components

Electrical Components

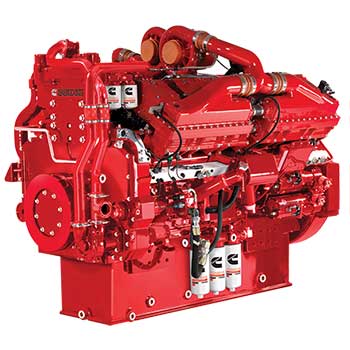

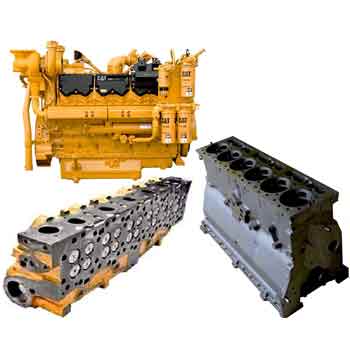

At Heavy Equipment Parts, we supply quality rebuilt engines, including Cummins QSK & KTA Series, Caterpillar C & 3500 Series, Komatsu SAA Serie & Perkins 4000 Series engines. Our commitment to excellence ensures that every rebuilt engine meets the highest standards of reliability and performance before shipping. We utilizes certified third-party repairers for the rebuilds and repairs of all diesel engines (Mine Spec).

Why Choose Rebuilt Engines on Service Exchange?

- Lower Cost: Quality rebuilt engines are generally less expensive than new ones, providing significant cost savings.

- Quick Turnaround: Service exchange programs often have rebuilt engines ready for immediate exchange, minimizing equipment downtime.

- Efficiency: Faster replacement of engines ensures that equipment is back in operation quickly, maintaining productivity.

- Certified Rebuilders: Rebuilt engines from certified rebuilders are restored to meet or exceed original specifications.

- Thorough Testing: These engines undergo rigorous testing to ensure reliability and performance.

- Warranty Coverage: Quality rebuilt engines often come with warranties similar to new engines, providing peace of mind and protection against defects.

- Dependable Performance: High-quality rebuilds ensure that the engine performs reliably, which is crucial in demanding applications like mining.

- Latest Technology: Quality rebuilt engines can incorporate the latest technological updates and improvements, enhancing performance and efficiency.

- Customization: Specific modifications can be made during the rebuild process to meet particular operational needs.

- Availability: Quality rebuilt engines can sometimes be more readily available than new ones, especially in situations where new engines are on backorder or have long lead times.

Our Engine Rebuild Procedures

When rebuilding an engine, we thoroughly inspected several key parts, then we recondition, or replaced to ensure the engine’s performance, reliability, and longevity. Here are the main parts that we check during a quality engine rebuild:

COMPONENT | SECTION | ACTION |

| Engine Block | Inspection for Cracks and Wear | The engine block is thoroughly inspected for cracks, warping, or excessive wear. |

Cylinder Bore 0000000000000000000000000 | Measure the cylinder bore for taper and out-of-round conditions. Re-bore or hone as necessary. | |

| Surface Flatness | Ensure the deck surface is flat and free of warps. | |

| Cylinder Head | Cracks and Warping | Check for cracks and warping. |

| Valve Seats | Inspect and recondition or replace valve seats. | |

| Valve Guides | Look for visible cracks & wear marks. Measure stem & inner diameter. Compare with OEM specifications and replace if necessary. | |

| Valve Springs and Retainers | Inspect for damage and proper tension, replace if needed | |

| Surface Flatness | Ensure the surface is flat and free of warps. | |

| Crankshaft | Journals and Bearing Surfaces | Measure for wear and scoring. Regrind if necessary. |

| Cracks | Check for cracks using magnaflux or similar techniques. | |

| Balance | Ensure the crankshaft is properly balanced. | |

| Camshaft | Lobes and Journals | Inspect for wear and scoring. Replace if worn. |

| Camshaft Bearings | Check for proper fit and replace if needed. | |

| Pistons and Connecting Rods | Piston Wear | Inspect for cracks, wear, and scoring. Replace if necessary. |

| Piston Rings | Replace piston rings and ensure proper fit. | |

| Connecting Rods | Check for straightness and balance. Replace if damaged. | |

| Bushings and Bearings | Inspect and replace connecting rod bushings and bearings. | |

| Bearings | Main Bearings | Inspect and replace main bearings. |

| 000000000000000000000000000 | Rod Bearings | Inspect and replace connecting rod bearings. |

| Thrust Bearings | Check and replace as necessary. | |

| Gaskets and Seals | Valves | Inspect valves for wear and damage, replace if necessary. |

| Valve Lifters | Check and replace lifters if worn. | |

| Pushrods | Inspect for straightness and wear. | |

| Rocker Arms | Check for wear and proper operation. | |

| Timing Components | Injectors | Test and clean or replace fuel injectors. |

| Fuel Pump | Inspect and replace if necessary. | |

| Fuel System Components | Injectors | Test and clean or replace fuel injectors. |

| Fuel Pump | Inspect and replace if necessary. | |

| Lubrication System | Oil Pump | Inspect and replace the oil pump. |

| Oil Galleries | Clean oil galleries to ensure proper lubrication. | |

| Cooling System | Water Pump | Inspect and replace the water pump. |

| Thermostat | Replace the thermostat. | |

| Radiator | Ensure the radiator is clean and in good condition. | |

| Intake and Exhaust System | Intake Manifold | Inspect and clean the intake manifold. |

| Exhaust Manifold | Inspect and clean the exhaust manifold. | |

| Ancillary Components | Belts and Hoses | Inspect and replace belts and hoses. |

| Filters | Replace oil, fuel, and air filters. | |

| Electrical Components | Glow Plugs | Replace glow plugs (for diesel engines). |

By thoroughly checking and addressing these components during an engine rebuild, we ensure that the rebuilt engine will perform reliably and efficiently. Each part plays a crucial role in the engine’s operation, and attention to detail in inspecting and reconditioning or replacing these parts is key to successful quality rebuild engines.

MODELS SUPPORTED

Cummins QSK & KTA Series, Caterpillar C & 3500 Series, Komatsu SAA Series & Perkins 4000 Series engines.

PRODUCT RANGE

QSK19, QSK45, QSK60, KTA19 KTA38, KTA50, C15, C18, C7, C27, C32, 3508, SAA6D140E-5, SAA6D170E-5

DISCLAIMER

CAT®, Komatsu®, Lierbherr®, Volvo®, Hitachi®, Bell® & Doosan® are trade brand registered by their owner and are only used for reference purpose of the application of our spare parts. Heavy Equipment Parts (Pty) Ltd utilizes certified third-party repairers for the rebuilds and repairs of all diesel engines (Mine Spec). These certified professionals adhere to stringent industry standards to ensure the highest quality and reliability of each rebuilt engine.